| Max Feed: 15 GPH (55 LPH) |

| Max Pressure: 175 PSI (12 bar) |

Description

-

- Max feed rate: 15 GPH / 55 LPH

- Max pressure: 175 PSI / 12 bar

- 4-20mA (C2V only), Pulse Input (C2V only) and Manual Speed Control

- Optional C2V communication protocols: Modbus, Profibus and Industrial Ethernet

- 166 RPM (Max strokes per minute)

- Variable speed, Smooth motor driven chemical feed

- Nema 4X washdown / IP 66

- Back Lit LCD display

- Leak Detection – Built-in Diaphragm Failure Detection (DFD)

- Exclusive Diaflex® Single Layer PVDF diaphragm.

Features

Benefits of a Diaphragm Pump:

- Capable of high pressures and high volume outputs.

- Non-loss motion variable speed DC motor is powerful, quiet and energy efficient

Capabilities:

- Feed rate resolution 0.1%

- Output rates to: 15 GPH (55 LPH) and pressures to 175 PSI (12 Bar).

Communication & Interface:

- SCADA ready 5-30V DC open collector output loop closes while motor is energized.

- Profibus DPV1, Profinet RT I/O, Industrial Ethernet/IP, Modbus RTU and Modbus TCP available

- Signal inputs include: 4-20mA, pulse inputs, and Remote start/stop

- Signal outputs include: Relay (3 amp), open collector, 4-20mA (optional)

- Upgradeable firmware

- Large, intuitive control-pad

- Backlit LCD displays motor speed, input signal values, service and alarm status.

- Includes Diaphragm Failure Detection (DFD) system.

- Compatible with Blue-White’s Flow Verification Sensor (FVS) system

- Alarm relay monitors the DFD system and the FVS system.

Superior Engineered Design:

- Protective LCD snap-on cover, (UV, in field wear and tear)

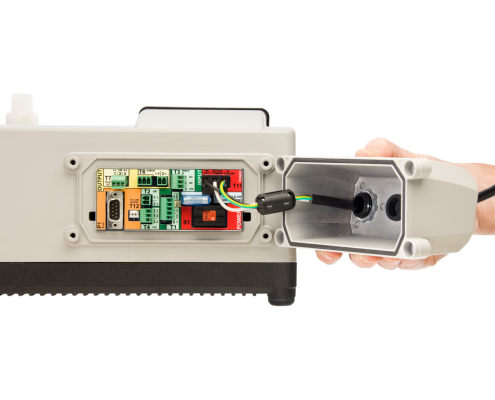

- Large single piece junction box with terminal block connectors inside

- Large PVDF, Ceramic, TFE/P double ball check valves without metal springs.

- Priming and degassing valve built into the pump head.

- Exclusive Diaflex™ Single Layer PVDF diaphragm.

- NEMA 4X (IP66) wash-down, chemically resistant powder coated enclosure.

Patents Pending:

- Exclusive Diaflex® Single Layer PVDF diaphragm.

Specifications

| Max. working pressure: | 175 psig (12 bar) |

| Max. fluid temperature: | 130° F (54° C) |

| Max. ambient temperature: | 14 to 110° F (-10 to 46° C ) |

| Maximum viscosity: | 1,000 Centipoise |

| Maximum suction lift: | 15 ft. Water, 0 psig (4.5 m, 0 bar) |

| Operating Voltage: | 115VAC/60Hz, 1ph (1.5 Amp Maximum) 230VAC/60Hz, 1ph (0.7 Amp Maximum) 220VAC/50Hz, 1ph (1.0 Amp Maximum) 240VAC/50Hz, 1ph (1.0 Amp Maximum) |

| Power Cord Options: | 115V60Hz = NEMA 5/15 (USA) 230V60Hz = NEMA 6/15 (USA) 220V50Hz = CEE 7/VII (EU) 240V50Hz = AS 3112 (Australia/New Zealand) |

| Duty cycle: | Continuous |

| Accuracy: | |

| Motor speed adjustment resolution: | 0.1% increments |

| Display: | Backlit LCD, UV resistant |

| Keypad: | Positive action tactile switch keypad |

| Enclosure: | NEMA 4X (IP66), Polyester powder coated aluminum. |

| Product weight: | 24lb. (10.9 Kg) |

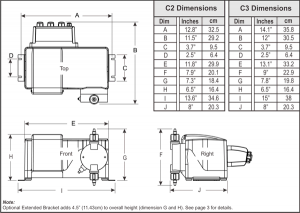

Dimensions

Literature

| LITERATURE |

|---|

| Instruction Manual PDF – C2V & C3V (PDF) (80000-516) |

| Instruction Manual PDF – C2F & C3F (PDF) (80000-514) |

| Technical Data Sheet (PDF) (85000-096) |

| DiaFlex® Retro-Fit Kit Information (PDF) (81000-363) |

| C2 & C3 Firmware Update Manual (PDF) (80000-525) |

| Case Study Farming Application |

Communication Protocols

| Instruction Manual – ETHERNET IP (PDF) (80000-533) |

| Instruction Manual – PROFIBUS (PDF) (80000-536) |

| Instruction Manual – PROFINET (PDF) (80000-537) |

| Instruction Manual – MODBUS RTU (PDF) (80000-531) |

| Instruction Manual – MODBUS TCP (PDF) (80000-532) |

Product Enquiry